FPV

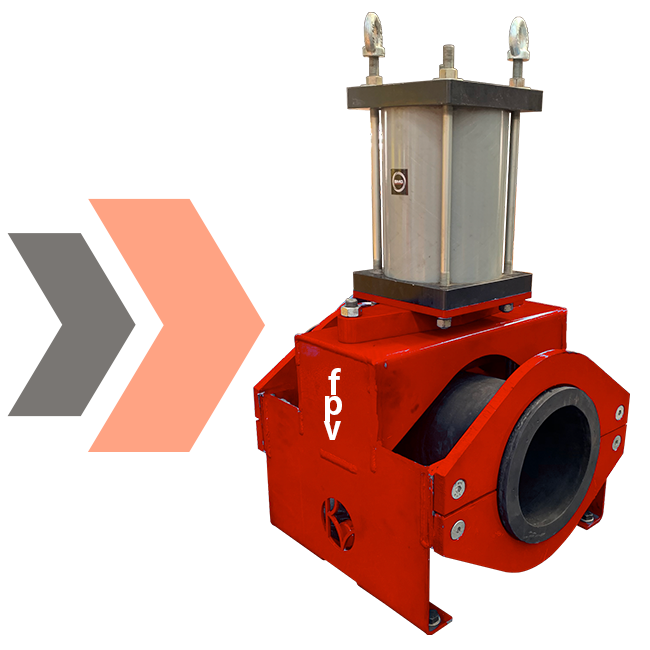

Pinch Valve Open Frame

FPV’s Pinch Valve consists of a tough, but flexible full bore sleeve, which forms part of the pipeline. The valve is closed mechanically via movement of the pinch bars located on opposite sides of the sleeve. The core of the FPV Pinch Valve is the sleeve. The sleeve is reinforced with high-strength fabric. The valves are well suited for on/off throttling applications where scale build-up is a problem.

Product features

Specifications

| Size range: | 2″ – 24″ (50mm – 600mm) |

|---|---|

| Valve type: | Pinch valve open frame |

| Body: | Flanged, fabricated steel |

| Temperature range: | 80°C |

| Pressure rating: | Up to 240 psi (16 bar) |

| Sleeve material: | Gum Rubber, EPDM, Neoprene, Nitrile, Butyl, Viton, Hypalon, Polyurethane. |

| Pinch bars: | Carbon steel |

| Pinch bar guides: | 304 Stainless Steel |

| Duty: | Abrasive applications |

| Hydro-static test: | 1.5 Times the rated pressure |

Features

- All types of actuators.

- Bellows.

- Centre pinch operation.

- Easy maintenance.

- Epoxy coated.

- Fabricated steel frame.

- Face to Face compatible with diaphragm valves.

- Full bore.

- Low-cost Pinch valve design.

- No blocking or leakage.

- No packing to maintain.

- Rising spindle with dust cover.

- Robust construction.

- Seals in both directions.

- Sleeves are available in a variety of materials.

- Sleeves are easily replaced.

- The open-frame design is lightweight, adaptable and economical.

- The sleeve is only wetted part.

How the valve operates

In the closed position, the upper and low bars compress the sleeve to from a bubble tight seal, even on entrapped debris. Because of the FPV Open frame design, the open/closed position of the valve can be viewed by sight. The valve can be used to throttle the flow.

Applications

The valve is suited for mining and mineral processing, power generation, sand/gravel, chemical & soda ash, pulp & paper, environmental, effluent, dry feeds and powders.

Actuators

All types of actuators can be fitted; electric, gearbox, hydraulic, pneumatic and handwheel.

Sleeve material

FPV offers the following alternative sleeve materials, providing chemical and abrasive resistance to most media such as:

- Natural black rubber

- Neoprene rubber

- Nitrile rubber

- Red rubber

Dimensions and Weights

Dimensions and weights are for guidance only – detailed dimension drawings are available on request.

All dimensions are in millimetres, unless otherwise stated.

| Valve Size | A/B F/F | C | D | E | SABS F/F |

|---|---|---|---|---|---|

| 50 | 170 | 240 | 375 | 300 | 191 |

| 80 | 220 | 290 | 480 | 300 | 254 |

| 100 | 250 | 320 | 520 | 400 | 305 |

| 150 | 255 | 400 | 630 | 400 | 406 |

| 200 | 400 | 420 | 630 | 450 | 521 |

| 250 | 500 | 500 | 770 | 450 | 635 |

| 300 | 600 | 600 | 900 | 600 | 749 |

| 350 | 685 | 700 | 1070 | 600 | 980 |

| 400 | 785 | 800 | 1230 | 600 | – |

| 450 | 880 | 900 | 1430 | 700 | – |

| 500 | 980 | 1000 | 1560 | 700 | – |

| 600 | 1180 | 1100 | 1690 | 700 | – |